Hello, welcome to visit the official website of Hubei Zhonghongtian Industrial Co., Ltd.

Hello, welcome to visit the official website of Hubei Zhonghongtian Industrial Co., Ltd.

Application of Sheet Metal Processing

2019-09-19 16:02

The processing steps of processing parts in sheet metal workshop are: pre-test of products, trial production of products and batch production of products. In the process of trial production, we should communicate with customers in time, get the evaluation of the corresponding processing, and then carry out mass production of products.

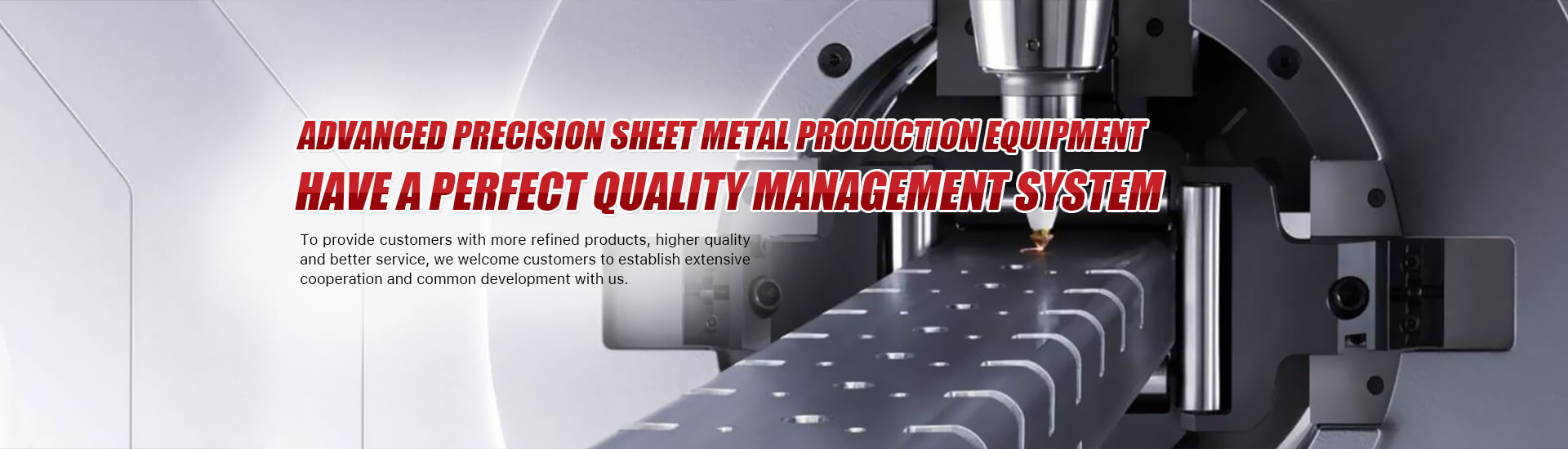

Laser drilling technology is the earliest practical laser technology in laser material processing technology. Laser drilling in sheet metal workshop generally uses pulsed laser, which has high energy density and short time. It can process small holes of 1 micron. It is especially suitable for processing small holes with a certain angle and thin material. It is also suitable for processing deep holes and micro holes on parts with higher strength and hardness or more brittle and soft materials.

Laser can drill the burner parts of gas turbine. The drilling effect can achieve three-dimensional direction, and the number can reach thousands. Perforable materials include stainless steel, nickel-chromium-iron alloy and HASTELLOY-based alloy. Laser drilling technology is not affected by the mechanical properties of materials, so it is easy to realize automation.

With the development of laser drilling technology, laser cutting machine has realized automatic operation. The application of laser cutting machine in sheet metal industry has changed the traditional processing method of sheet metal technology, realized unmanned operation, greatly improved production efficiency, realized full automatic operation, promoted the development of sheet metal economy, and in the aspect of punching effect. Upgraded a grade, the processing effect is remarkable.

NEWS CENTER

Welcome customers to establish extensive cooperation and common development with usProcess flow of sheet metal punching

Selection of Materials The materials commonly used in sheet metal processing are cold-rolled sheet (SPCC), hot-rolled sheet (SHCC), galvanized sheet (SECC, SGCC), copper (CU), copper, beryllium copper, aluminium sheet (6061, 5052, 1010, 106The Function of Sheet Metal Bending Proce

The bending and forming of sheet metal sheet metal in bending machine are carried out. The workpiece to be formed is placed on the bending machine. The brake shoe is lifted by lifting lever, the workpiece slides to the appropriate position,Brief Introduction of Sheet Metal Technol

Sheet metal work is a kind of work developed in the early 1990s. Its predecessor is cold work. Now we are generally classified as follows: thick sheet metal: 3 mm thick sheet metal forming processing, because of thickness reasons, this kindApplication of Sheet Metal Processing

The processing steps of processing parts in sheet metal workshop are: pre-test of products, trial production of products and batch production of products. In the process of trial production, we should communicate with customers in time, getProblems to be Considered in Sheet Metal

Sheet metal is the material that most mechanical equipment must use, such as machine tools, cabinets, chassis, etc. Because of the special material properties and processing requirements of sheet metal itself, there are strict requirements

Lead Form